The Hubei Xianghua Machine held a kick-off meeting for the Lean Benchmark Factory Planning Project.

Classification: Company Dynamics

Time2024-07-02

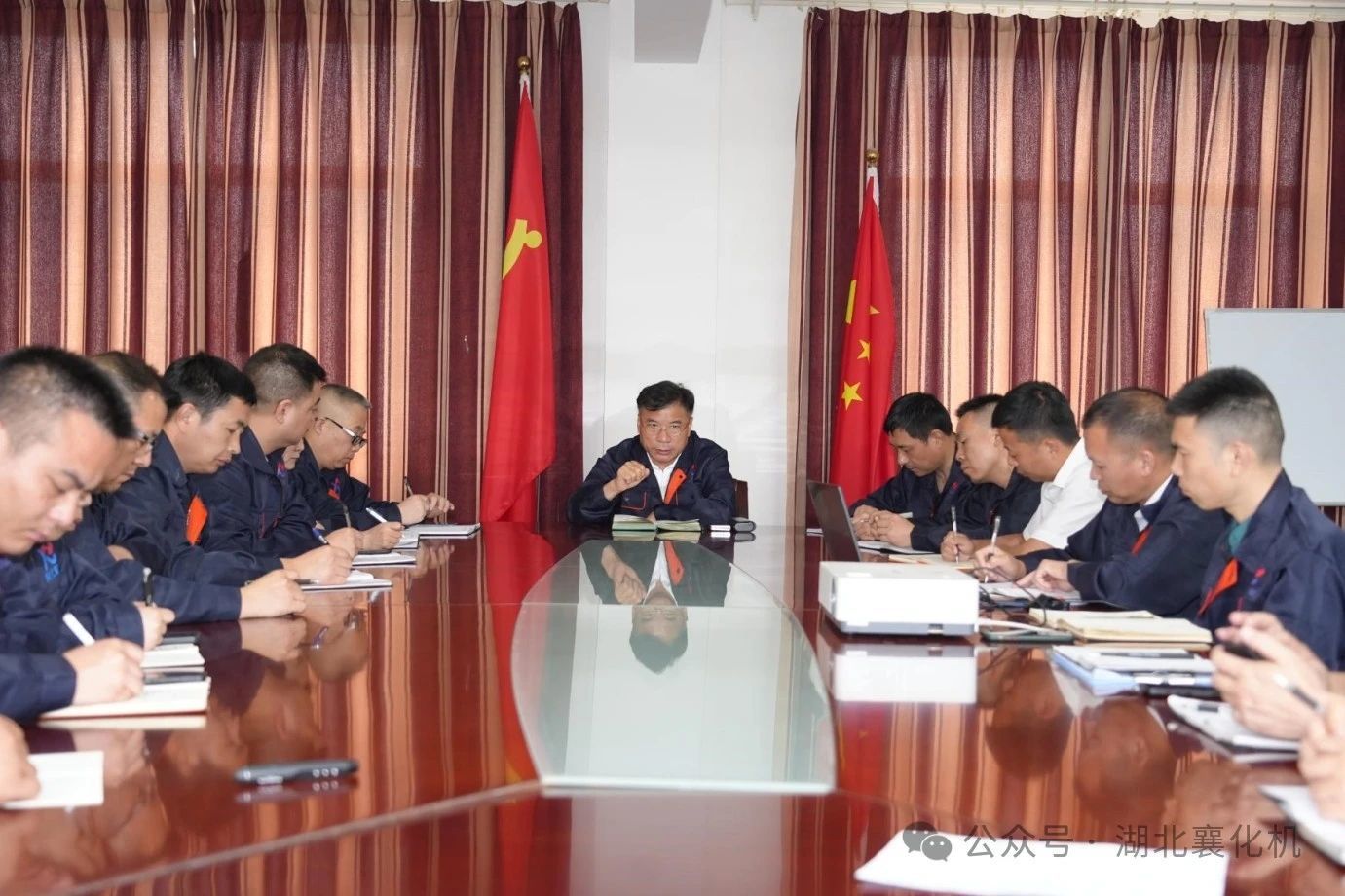

In order to build a lean benchmark factory, comprehensively improve the production efficiency and effectiveness of the enterprise, enhance product quality, and further strengthen the company's market competitiveness, Hubei Xianghua Mechanical Equipment Co., Ltd. has introduced a professional consulting management company and recently held a meeting.Kick-off meeting for the lean benchmark factory planning project, Chairman of Hubei Xianghua Machinery, and leader of the lean benchmark factory planning project groupXiang Huailinled more than 20 group members and personnel from production and production support departments to attend the conference.

In the tide of the digital age, the rapid development of Industry 4.0 technology is profoundly changing the landscape of the manufacturing industry. With the widespread application of new generation information technologies such as the Internet of Things, big data, and cloud computing,factory layoutthe importance of optimizing production processes, improving production efficiency, production effectiveness, ensuring product quality, and enhancing the comprehensive competitiveness of enterprises is becoming increasingly prominent.

This year, Hubei Xianghua Mechanical Equipment Co., Ltd. is closely following the national developmentnew quality productivitystrategic pace, continuously promoting new industrialization development, renovating and upgrading old production sites, while implementing lean layout planning, aiming to achieveefficient and intelligent production processesto cope with fierce market competition.

At the beginning of the kick-off meeting, the Minister of Human Resources of Hubei Xianghua MachineryYang Mingprovided an in-depth introduction to the background of the 'Lean Benchmark Factory Planning Project' to the participants. Minister Yang first reviewed the development history of Hubei Xianghua Machinery in recent years, mentioning that with the increasing intensity of market competition, the traditional production management model can no longer meet the rapid development needs of the company. By implementing lean production management, the company can maximizethe reduction of waste in the production process.

01Lean Layout Planning Training&Detailed Explanation of the Plan

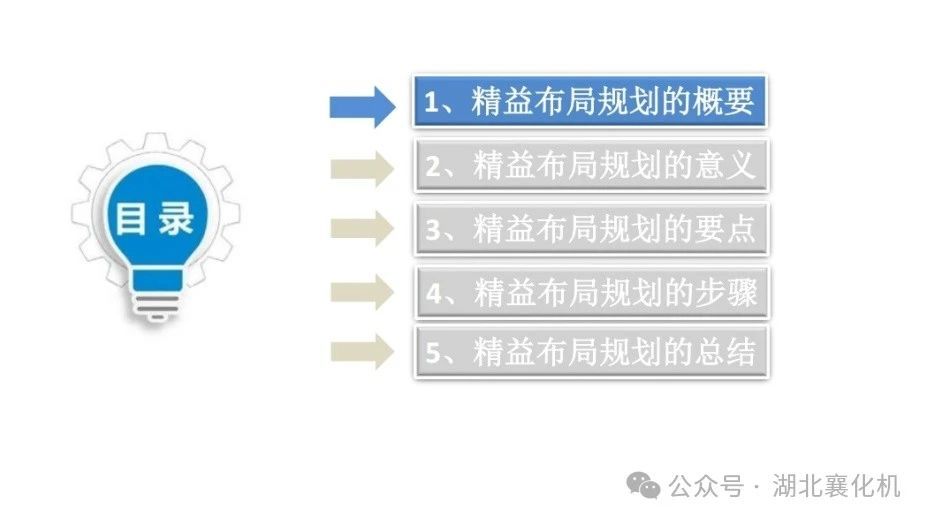

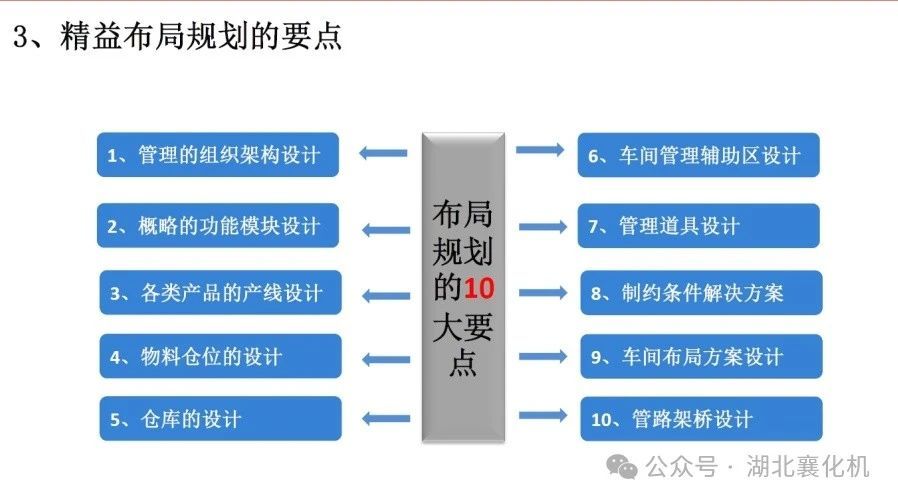

Lecturer Xu from the Lean Benchmark Factory Planning Project provided a detailed training on lean layout planning and implementation plans.

Xu elaborated on the core concepts of lean layout, focusing onthree key elements: rationality, flexibility, and sustainability. He analyzed the key implementation throughten major pointsand systematically sorted out the entire process of lean layout witheight major stepsas a framework. Through Xu's explanation, the participants gained a deeper understanding of lean layout, providing strong support for the enterprise to achieve lean management.

02Speech by the Leader of the Lean Benchmark Factory Planning Project

Chairman of Hubei Xianghua Machinery and leader of the lean benchmark factory planning projectXiang Huailinsummarized his speech, stating that lean benchmark 6S management is not only the key to improving the overalloperational efficiency, effectiveness, and product quality, thereby enhancing market competitiveness; it is also an important cornerstone for creating an efficient working environment for employees, improving professional quality, and promoting career development.

Xiang pointed out that the advancement of the lean benchmark factory planning projectis not an overnight successand requires continuous efforts to ensure that the results can be consolidated and expanded. Therefore, he hopes that everyone can maintain high morale and a rigorous work attitude, actively participate in various tasks of the project.

- Deeply understand and recognize the concept of lean benchmark 6S management, which is not only a means to improve work efficiency and quality but also an important way to shape corporate culture and enhance employee quality.

- Actively participate and put it into practice, starting from oneself and from small matters.

- Strengthen teamwork and communication, pooling wisdom.

- Ensure safety, putting safety first.

- Focus on timeliness and continuous improvement.

Strengthen supervision and feedback mechanisms, adjusting in a timely manner.

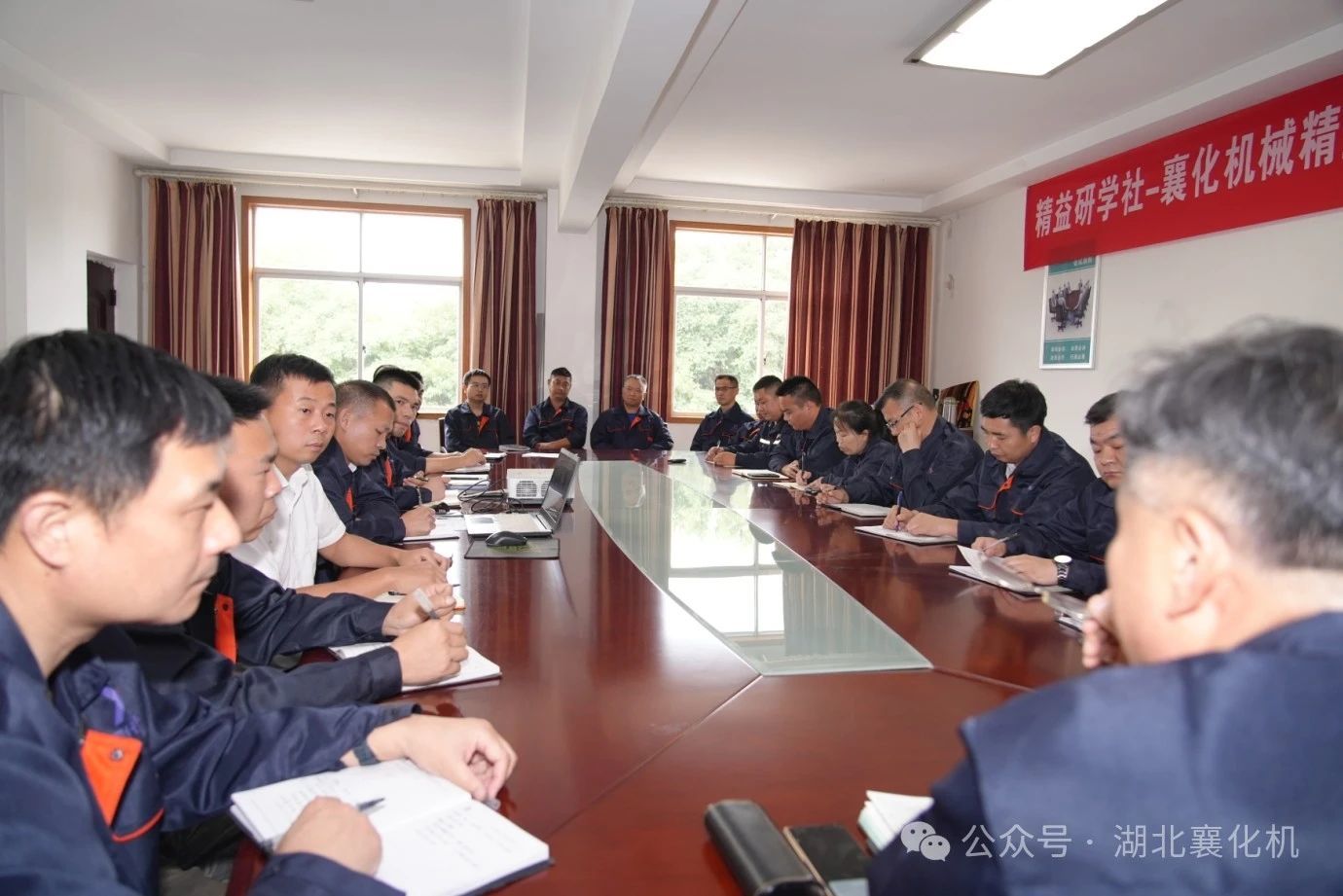

03 Communication and Discussion Session

Through the training, everyone has deeply mastered the basic knowledge and specific methods and techniques of lean layout planning, laying a good foundation for the smooth promotion of future projects. In the interactive session, everyone actively spoke, sharing their insights based ontheir own job realities.04 Project Team Oath

During the oath-taking ceremony, the Minister of Human Resources of Hubei Xianghua Machinery, Yang Ming, led all personnel in a solemn oath: 'We will always adhere to the production philosophy of 'lean production, safe and efficient', insist on lean management, and reduce costs and increase efficiency through the effective operation of lean 6S visual management activities, continuously change management thinking, improve work methods, transform work styles, achieve leadership attention, full participation, continuous improvement, and form the visual management culture of lean 6S in Hubei Xianghua Machinery.'

Lean management focuses on practice and is valuable in implementation. In the future, Hubei Xianghua Machinery will continue to implement the relevant requirements of lean management layout, continuously deepen management innovation, optimize production processes, improve product quality, reduce production costs, provide strong support for the company's high-quality development, and offer higher value to meet customer needs.北襄化机人资部部长杨明带领全体人员进行了庄严宣誓:“将始终秉承着“精益生产,安全高效”的生产理念,坚持精益管理,坚持降本增效,通过精益6S目视化管理活动的有效运行,不断改变管理思维,改善工作方式,转变工作作风,实现领导重视,全员参与,持续改善,形成湖北襄化机械精益6S目视化管理文化。”

精益管理重在实践、贵在落实。未来,湖北襄化机将持续落实精益管理布局的相关要求,不断深化管理创新,优化生产流程,提高产品质量,降低生产成本,为公司的高质量发展提供有力保障,为满足客户的需求提供更高的价值。

Keyword: The Hubei Xianghua Machine held a kick-off meeting for the Lean Benchmark Factory Planning Project.

RELATED INFORMATION

Company Dynamics

-

Prospective clients visited Hubei Xiang Hua Machinery for inspection and exchange

Time:2025-05-10

-

"Cultivation and Application Integration" New Exploration: In-depth Cooperation Between Xiangyang Human Resources Agencies and Zhongbo Welding School

Time:2025-04-29

-

Hubei XiangHuaJi was awarded the "2024 Hubei Provincial Manufacturing Industry Single-Item Champion Enterprise"

Time:2025-04-29

-

Visit from German environmental giant! Hubei Xiang Hua Machinery wins new opportunities for localized production cooperation with its hard-core strength

Time:2025-04-09

-

The BaoKang County Employment Bureau organized a group to inspect the ZhongBo Welding Training School under Hubei XiangHua Machinery.

Time:2025-04-01

-

Laohukou Municipal Human Resources and Social Security Bureau leaders investigated Xiang Hua Machinery's Zhongbo Welding School, jointly exploring new paths for 'industry-education integration'.

Time:2025-03-25

-

Hubei Xiang Hua Machinery conducts internal training on "Organizational Growth and Efficient Execution"

Time:2025-03-14

-

The Ministry of Finance conducted a survey of Zhongbo Welding Training School, a subsidiary of Xiang Hua Machinery in Hubei Province

Time:2025-03-12

-

Hubei Xianghua Machinery demonstrates the dual responsibility of corporate strength and social responsibility, winning the favor of potential clients again.

Time:2025-02-27

-

Hubei Xianghua Machinery conducts DeepSeek application and practice training, Chairman Xiang Huailin emphasizes the opportunities and challenges of AI intelligence.

Time:2025-02-26

-

Strive for a "good start" in the first quarter, work hard to achieve excellent results.

Time:2025-02-25

-

Hubei Xianghua Machine made its appearance at the Xiangyang "Spring Breeze Action" job fair, offering over 70 quality job positions.

Time:2025-02-07

-

Hubei Xianghua Machinery undertakes the overall delivery of 300,000 cubic meters/day gas liquefaction skid-mounted equipment.

Time:2025-01-18

-

Hubei Xianghua Machinery | Zhongbo Welding Skills Training Helps Improve Skills and Increase Employment Income for the Public

Time:2025-01-14

-

Hubei Xianghua Machinery | Lean Improvement in Action (Part 1)

Time:2025-01-08

-

2025 is here with a fresh start | The official website of Hubei Xianghua Machinery has been completely upgraded and launched.

Time:2025-01-06

-

Striving for new achievements and creating a new situation | Hubei Xianghua Machinery 2024 Year-End Summary

Time:2025-01-04

-

Unwavering in our mission, we forge ahead to write a new chapter - New Year’s message for 2025 from Chairman Xiang Hualin of Hubei Xianghua Machinery.

Time:2025-01-03

-

The second welding skills competition for Xianghua Machinery interns and graduates of Zhongbo Welding School has successfully concluded.

Time:2025-01-02

-

Chairman Kang Heping of Sanbao Group and his delegation visited and exchanged ideas at Hubei Xianghua Machine.

Time:2024-12-18

-

Xianghua Machinery is fully operational in the fourth quarter, busy with deliveries, striving to achieve a 'full house' success!

Time:2024-11-18

-

The first party branch of the Human Resources and Social Security Bureau of Xiangyang City and the temporary party branch of the seventh inspection team of the municipal party committee visited for research.

Time:2024-10-28

-

Fighting for a "Year-Round Red", Hubei Xianghua is busy with multi-line operations.

Time:2024-09-29

-

The Secretary of the Party Leadership Group and Director of the Hubei Provincial Human Resources and Social Security Department came to the Hubei Xianghua Welding School for research.

Time:2024-09-27

-

Hubei Xianghua Machinery participated in the "Oil and Natural Gas Exhibition" with a focus on: the comprehensive utilization of waste mineral oil recycling and the LNG natural gas project receiving significant attention!

Time:2024-09-25

-

Hubei Xianghua Machinery will participate in the 29th Kazakhstan International Oil and Gas Exhibition in 2024.

Time:2024-09-24

-

Hubei Xianghua machinery manufacturing has taken solid steps towards high-quality development.

Time:2024-08-26

-

Stirring device of reactor manufacturer equipment

Time:2024-07-09

-

The Hubei Xianghua Machine held a kick-off meeting for the Lean Benchmark Factory Planning Project.

Time:2024-07-02

-

Hubei Xianghua organized a "July 1" themed party day event to celebrate the 103rd anniversary of the founding of the Party.

Time:2024-07-01

-

Join hands to build the "Belt and Road" and explore a new chapter of prosperous future | Hubei Xianghua Machinery visits friendly cooperative foreign trade enterprises

Time:2024-06-17

-

Introducing advanced production equipment, the orders for Hubei Xianghua Machinery are accelerating!

Time:2024-06-08

-

Hubei Xianghua Machinery and Hubei University of Technology jointly build a high-quality school-enterprise cooperation model.

Time:2024-06-01

-

Important partner from Xianghua, Hubei visits the production site to conduct a comprehensive inspection of the skid-mounted equipment production!

Time:2024-05-27

-

Hubei Xianghua Machine was invited to participate in the Hubei Province "Manufacturing Leaders" industry chain and supply chain docking event.

Time:2024-05-18

-

Hubei Xianghua Machinery Equipment signed a strategic cooperation agreement with Greeenmei for a trade-in program.

Time:2024-05-07

-

Promoting the development of new quality productivity with equipment updates | Hubei Xianghua Machine introduces a brand new automatic welding machine for edge beams

Time:2024-05-06

-

Hubei Xianghua machinery equipment is making solid progress, showcasing a new style in the pressure vessel manufacturing industry.

Time:2024-04-30

-

Empowerment through Learning | "PDCA Cycle Work Method" Training and "New Quality Productivity" Study

Time:2024-04-23

-

14 stainless steel reactors manufactured by Hubei Xianghua Machinery Equipment have been shipped.

Time:2024-04-09

-

Xianghua Machinery Equipment has completed the delivery of 3 stainless steel reactors for Hubei Benxing New Energy Company.

Time:2024-03-16

-

Xianghua Machinery Equipment has completed the delivery of 3 stainless steel reactors for Hubei Benxing New Energy Company.

Time:2024-03-08

-

Xianghua Machine held a monthly meeting to deploy and promote key work.

Time:2024-02-29

-

【Spring Festival does not stop work, striving to ensure delivery】 14 phosphorus reactors from Hubei Darun successfully delivered

Time:2024-02-19

-

湖北襄化机2024年年会暨颁奖典礼圆满举行

Time:2024-02-06

-

Technical analysis of new DMF composite solvent refining process in Hubei chemical machinery

Time:2020-06-18

-

The construction of 8 expressways in Xiangyang City is progressing in an orderly manner, which is beneficial for the development of the waste oil recycling industry.

Time:2020-06-18

-

How Hubei Chemical Machinery Strengthens the Heat Transfer Performance of Fin Tube Heat Exchangers

Time:2019-01-19

-

Enhanced heat transfer technology for shell and tube heat exchangers in Hubei chemical machinery

Time:2019-01-19

-

The general types of methods for enhancing heat transfer in Hubei chemical machinery shell courses.

Time:2019-01-19

Industry Information

-

Customized solutions from non-standard pressure vessel manufacturers

Time:2025-12-23

-

Overview of chemical storage tank manufacturers and materials

Time:2025-04-25

-

Stainless steel liquid ammonia storage tank manufacturers

Time:2025-04-15

-

Working principle of stainless steel reaction kettle

Time:2025-04-08

-

Advantages of Material Selection by Pressure Vessel Manufacturers

Time:2025-03-31

-

Advantages of Pressure Pipeline Installation Manufacturers

Time:2025-03-24

-

Advantages of Liquid Ammonia Storage Tank Manufacturers

Time:2025-03-20

-

Application scenarios and material selection of stainless steel reaction kettles

Time:2025-03-17

-

Manufacturing Process and Standards for Pressure Vessels

Time:2025-03-07

-

The application prospects of stainless steel storage tanks in the environmental protection field

Time:2025-02-28

-

Stainless Steel Reactor

Time:2025-02-20

-

Customers interested in Hubei Xianghua machinery visited for inspection and communication, seeking to jointly explore a new chapter of development.

Time:2025-02-18

-

Stainless Steel Reactor Manufacturing Factory

Time:2025-02-12

-

Stainless Steel Tank / Pressure Vessel Manufacturing Manufacturer

Time:2025-02-08

-

Pressure vessel manufacturing factory

Time:2025-01-16

-

Chemical storage tank manufacturing factory

Time:2025-01-10

-

The working principle of a tubular heat exchanger

Time:2024-12-25

-

Safety operation procedures for pressure vessel manufacturers

Time:2024-12-17

-

Inspection items and cycles for chemical storage tanks

Time:2024-12-13

-

What are the methods for corrosion prevention of storage tanks? Construction plan for corrosion prevention of the inner wall of storage tanks.

Time:2024-12-09

-

Inspection items of chemical storage tank manufacturers

Time:2024-12-03

-

How do heat exchanger manufacturers repair corrosion?

Time:2024-11-28

-

Causes of heat exchanger corrosion

Time:2024-11-26

-

Classification of heat transfer principles in heat exchanger manufacturers

Time:2024-11-20

-

Xianghua Machinery is fully operational in the fourth quarter, busy with deliveries, striving to achieve a 'full house' success!

Time:2024-11-18

-

Advantages of stainless steel condenser manufacturers

Time:2024-11-16

-

Maintenance and Inspection of Chemical Storage Tank Manufacturers and Usage Precautions

Time:2024-11-11

-

Precautions for the manufacturing and installation of tank manufacturers

Time:2024-11-07

-

Tank manufacturer production and installation construction plan

Time:2024-11-05

-

What are the differences between horizontal tanks and vertical tanks? Which one should be chosen, horizontal or vertical tanks?

Time:2024-10-30

-

Classification of manufacturers of tubular heat exchangers

Time:2024-10-25

-

Heating methods of reaction vessels

Time:2024-10-22

-

Introduction to the function and principle of the reactor stirrer

Time:2024-10-09

-

What is the typical capacity of an LNG liquefied natural gas storage tank?

Time:2024-10-07

-

How to choose a manufacturer of stainless steel storage tanks

Time:2024-10-05

-

The lean benchmark factory project continues to advance, empowering industrial upgrades and optimizing customer value experience.

Time:2024-09-30

-

Design specifications and requirements for liquid ammonia storage tank manufacturers

Time:2024-09-24

-

What are the classifications of chemical storage tank manufacturers?

Time:2024-09-18

-

Classification of equipment for pressure vessel manufacturers

Time:2024-09-15

-

What conditions must a pressure vessel manufacturer meet to be considered a special equipment?

Time:2024-09-12

-

What are the operating conditions of pressure vessel manufacturers?

Time:2024-09-09

-

Types of safety accessories and inspection cycles for pressure vessel manufacturers

Time:2024-09-06

-

Basic requirements for material selection by pressure vessel manufacturers

Time:2024-09-03

-

The Deputy Director of the Provincial Human Resources and Social Security Department, the Secretary of the Party Committee and Director of the Provincial Labor and Employment Service Center, and their delegation visited the Xiangyang Zhongbo Welding Skills Training School under Hubei Xianghua Machine for research.

Time:2024-08-31

-

What materials are used by pressure vessel manufacturers? What is the manufacturing process of pressure vessels?

Time:2024-08-28

-

Measures taken by pressure vessel manufacturers to prevent accidents

Time:2024-08-26

-

Regular inspection content for pressure vessel manufacturers

Time:2024-08-21

-

How often should pressure vessels be inspected? What is the service life of pressure vessels?

Time:2024-08-17

-

Manufacturing process of stainless steel storage tank manufacturers

Time:2024-08-12

-

Analysis of the structure of common storage tanks by storage tank manufacturers

Time:2024-08-08

-

Safety precautions for the use of reaction vessels

Time:2024-08-05

-

The five major components of the pressure vessel shell outside the cylinder body

Time:2024-07-30

-

Theoretical Manufacturing and Main Characteristics of Pressure Vessel Manufacturers

Time:2024-07-27

-

Composition of the cylinder body in pressure vessel manufacturing

Time:2024-07-24

-

Pressure vessel equipment manufacturer

Time:2024-07-22

-

Inspection and testing standards for atmospheric pressure storage tank manufacturers

Time:2024-07-16

-

Classification of reactor equipment manufacturers

Time:2024-07-05

-

Classification and maintenance of condensers

Time:2024-06-26

-

The difference between evaporators and condensers

Time:2024-06-22

-

Precautions for Using Heat Exchanger Manufacturers

Time:2024-06-17

-

Tube-type heat exchanger - heat exchanger manufacturer

Time:2024-06-11

-

Advantages and disadvantages of floating head and U-tube heat exchangers

Time:2024-06-07

-

Classification of heat exchanger manufacturing - heat exchanger manufacturers

Time:2024-06-03

-

Basic knowledge of plate heat exchangers

Time:2024-05-30

-

Heat exchanger production process

Time:2024-05-20

-

Considerations for Choosing a Reactor Manufacturing Factory

Time:2024-05-16

-

Characteristics of the products from the manufacturer of reactor equipment

Time:2024-05-11

-

Classification of Chemical Storage Tanks - Tank Production Manufacturers

Time:2024-05-04

-

Precautions for Using Stainless Steel Reactors Produced by Pressure Vessel Manufacturers

Time:2024-04-30

-

Structural performance and advantages of stainless steel reactors

Time:2024-04-27

-

Difference between stainless steel reactors and enamel reactors

Time:2024-04-17

-

Welding between mechanical equipment components of pressure vessels

Time:2024-04-12

-

Basic knowledge of openings and pipe connections in pressure vessel shells

Time:2024-04-08

-

Pressure vessel combined cylinder and sealing device

Time:2024-03-29

-

Introduction to Single-Layer Cylindrical Pressure Vessels

Time:2024-03-26

-

Basic structure of pressure vessel equipment manufacturing

Time:2024-03-21

-

Installation process and construction key points of pressure pipelines

Time:2024-03-14

-

Requirements for the safety technology of pressure vessels

Time:2024-03-09

-

The difference between single-layer and double-layer enamel reaction kettles

Time:2024-03-05

-

What is a pressure vessel? What are the precautions for using pressure vessels?

Time:2024-02-29

-

Safety management of mechanical engineering equipment

Time:2024-01-31

-

Seven Major Safety Supervision Guidelines for Pressure Vessel Special Equipment

Time:2024-01-22

-

Product features of stainless steel reaction kettle

Time:2024-01-10

-

What types of stainless steel tanks are there for pressure vessel equipment?

Time:2023-12-28

-

Chemical machinery - Manufacturing demand for storage equipment for hazardous waste enterprises that regenerate waste oil into base oil.

Time:2020-07-11

-

Design Principles for Hazardous Waste Storage Facilities for Comprehensive Utilization of Waste Mineral Oil

Time:2020-06-30

-

Requirements for the site selection of storage facilities for waste oil regeneration base oil enterprises

Time:2020-06-27

-

Chemical Machinery - The first promotion meeting of the Green Full Xiangyang Re-Upgrade Action in Xiangyang City was held.

Time:2020-06-27

-

Chemical machinery - disposal and utilization of waste mineral oil, common illegal activities

Time:2020-06-23

Exhibition style

-

Exhibition style

Time:2024-11-21

-

Exhibition style

Time:2024-11-21

-

Exhibition style

Time:2024-11-21

-

Exhibition style

Time:2024-11-21

-

Exhibition style

Time:2024-11-21

-

Exhibition style

Time:2024-11-21

-

Exhibition style

Time:2024-11-21

-

Exhibition style

Time:2024-11-21

-

Exhibition style

Time:2024-11-21

-

Exhibition style

Time:2024-11-15

-

Exhibition style

Time:2024-11-15

-

Exhibition style

Time:2024-11-15

-

Exhibition style

Time:2024-11-15

-

Exhibition style

Time:2024-11-15

-

Exhibition style

Time:2024-11-14