Intelligent tube sheet robot

tube sheet robot

Product overview

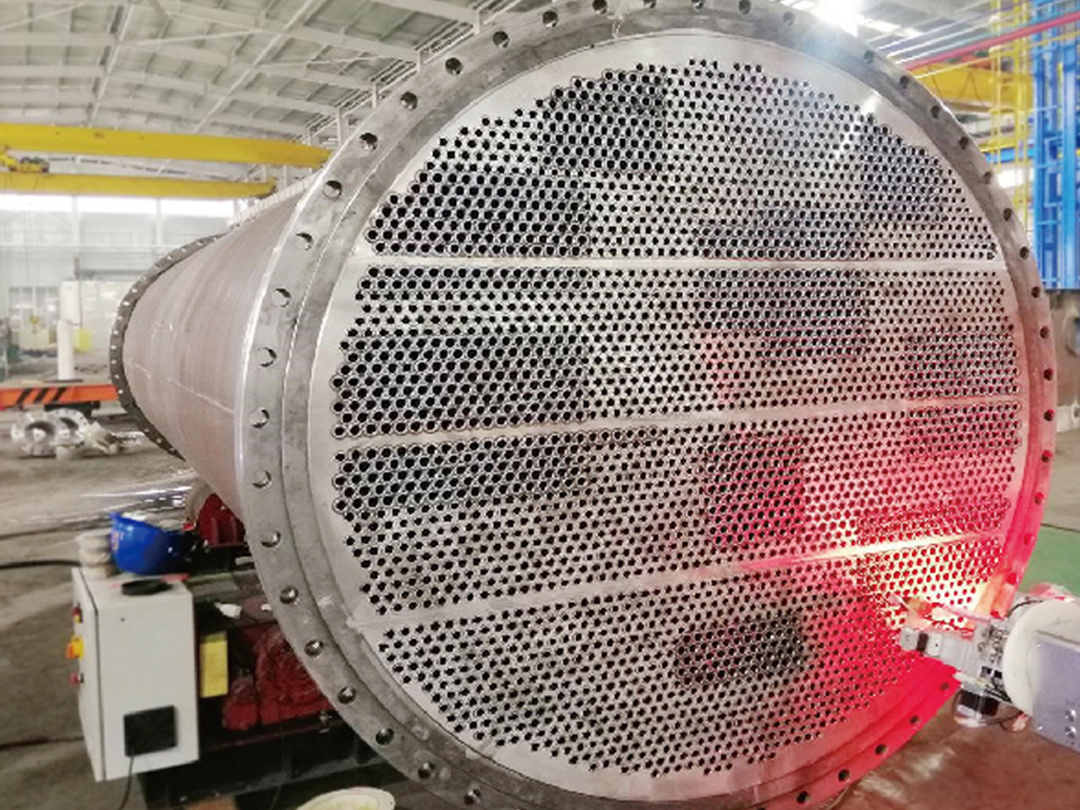

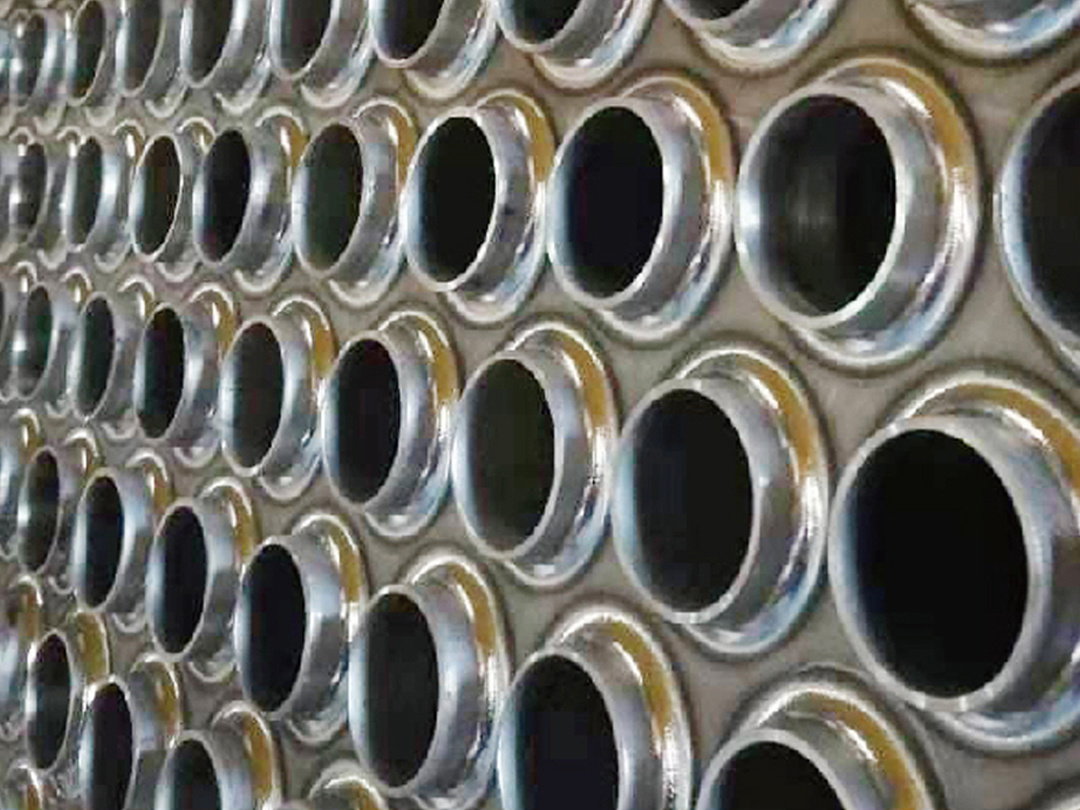

◎This system is suitable for fillet welding and flat welding of tube-tube plate;

◎Welding joint material: carbon steel, stainless steel;

◎Pipe specification: pipe diameter is 10-80mm (standard diameter Φ 10-50 lens, other lens above Φ 50 need to be purchased), wall thickness is between 1-5mm;

◎Tube plate material: carbon steel, stainless steel;

◎Tube extension length: fillet weld 4-6mm;

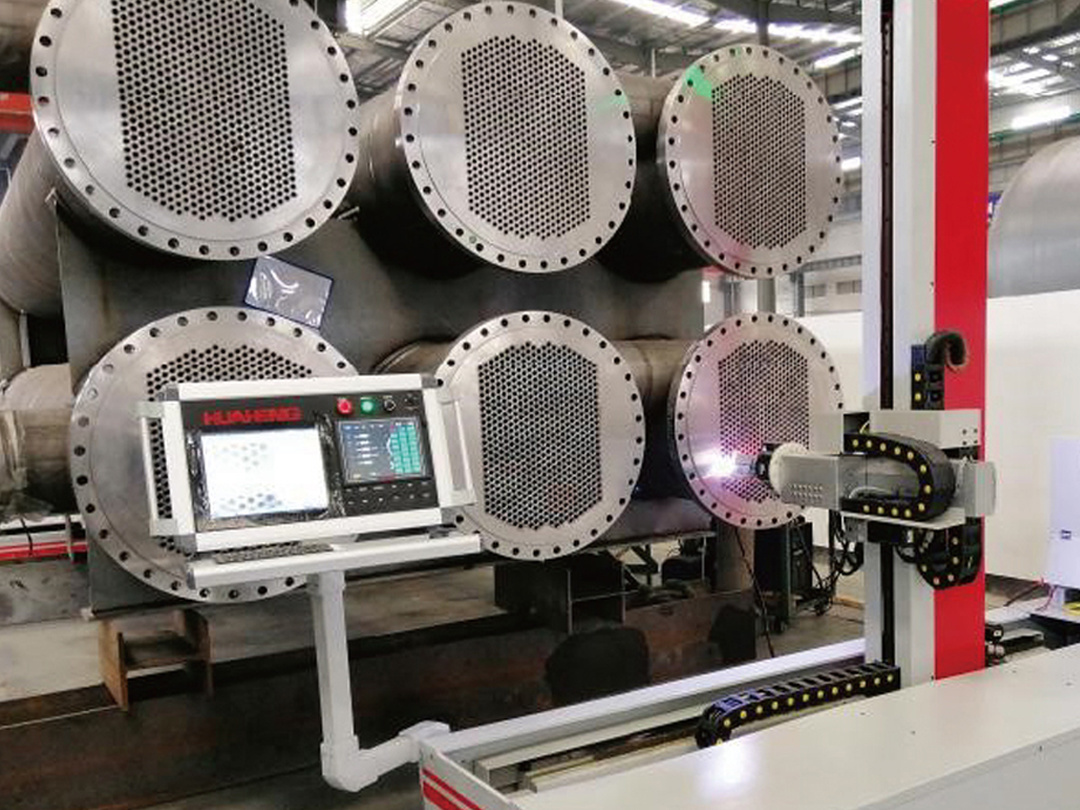

◎The main purpose of this system is to solve the unmanned operation of the tube plate, high-efficiency TIG welding, one-person multi-machine control, improve production efficiency, reduce labor intensity;

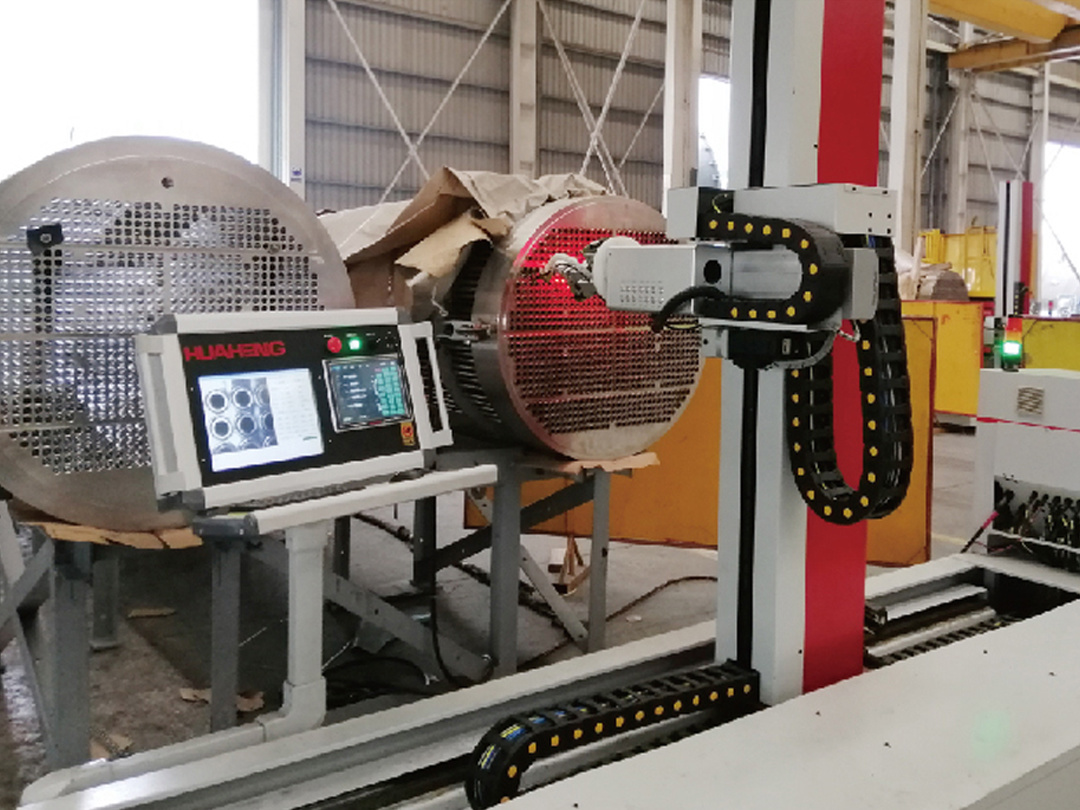

◎This system consists of KUKA robot, vision system, program-controlled welding power supply, special welding head, data acquisition system, etc;

◎The complete system adopts KUKA and Huaheng's mature TIG welding equipment and technology to ensure efficient, stable and reliable welding quality.

Performance characteristics

◎The robot first measures the distance between the gun head and the tube plate by laser;

◎The robot measures the inner diameter and outer diameter of each pipe diameter within the range of 100*100mm by photographing, so that the specific position of all pipes can be measured by photographing for many times, and background calculation can be carried out;

◎The robot holds the tube plate welding gun accurately and quickly to the required position of each tube

◎The welding program is started, and the automatic tube plate welding is carried out. During the welding process, the automatic tracking is opened to ensure the smooth welding of all positions;

◎The robot automatically calculates the number of welding joints, and alarms to manually replace the tungsten pole when the number of welding joints is set for each welding;

◎1KG/disc welding wire shall be adopted, and the robot shall give an alarm to manually replace the welding wire;

◎The entire welding process, without manual intervention (except for changing the welding wire and tungsten electrode);

◎One person can manage the welding of 3-4 robots;

Technical parameters

| Weldable material |

Carbon steel, stainless steel, titanium alloy (with support cover) |

| Weldable pipe diameter (mm) |

Φ10~Φ80 (standard diameter 10-50 lenses, other lenses need to be purchased above Φ50) |

| Tube sheet form |

Tube extension, tube flush, tube contraction |

| Rotation speed (rpm) |

0.3~5.9 |

| Rotation accuracy error |

≤ 5% |

| Torch Inclination |

0 ° ~ 30 ° adjustable |

| Arc length adjustment spacing (mm) |

20 |

| Maximum wire feeding speed (mm/min) |

1800 |

| wire feeding accuracy error |

≤ 5% |

| Accuracy error of arc length (v) |

≤ 0. 1 |

| Protective gas |

Argon |

| Cooling mode |

Water cooling |

| Cooling flow (ml/min) |

≥ 300 |

| Rated current |

300A Temporary Load Rate 60% |

| Weight (kg) |

12 (without cable) |

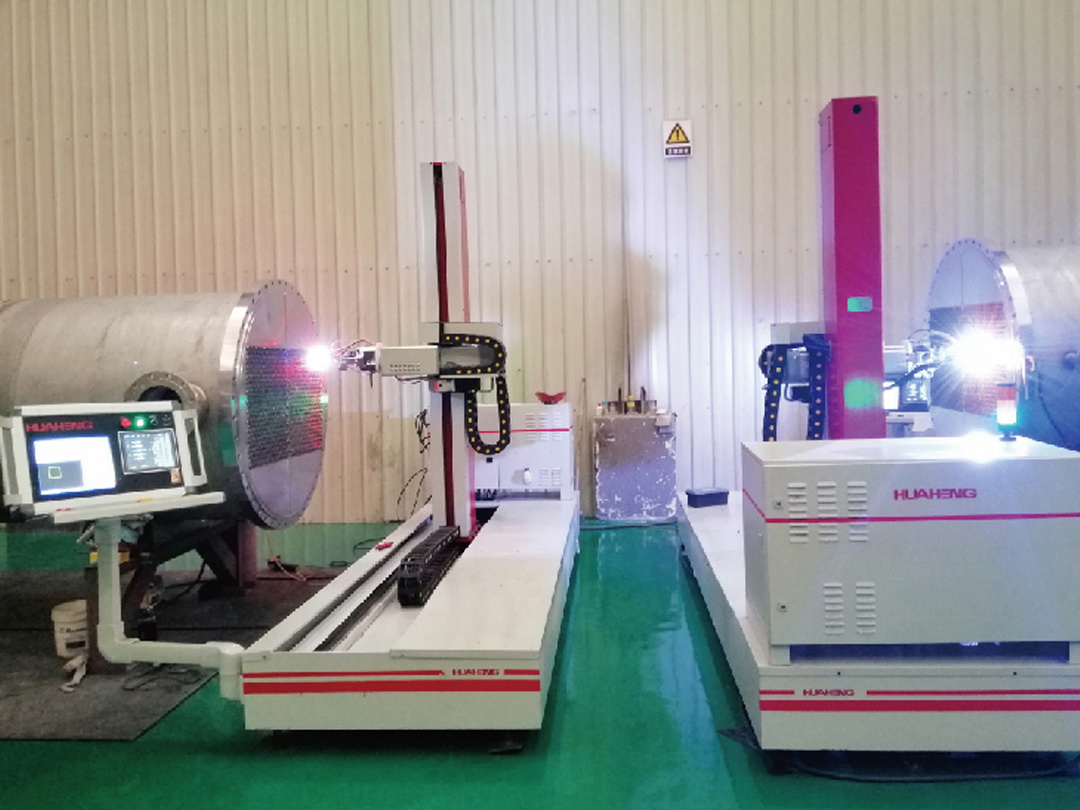

Intelligent Tube Sheet Robot Welding System

Technical parameters:

| TPR2000 (overall dimension mm) |

4200*1340*3040 |

| TPR3000 (overall dimension mm) |

5000*1340*3940 |

| Scope of welded pipe (mm) |

Φ10~Φ80 (camera with corresponding focal length according to pipe diameter) |

| Welding current (A) |

5~500 |

| Welding material |

Carbon steel, stainless steel, titanium alloy |

| Joint type |

Tube flush, tube extended |

| Welding process |

TIG self-fusing or wire |

| Protective gas |

Argon |

| Angle range of welding tool |

-10°~30° |

| Diameter of welding wire (mm) |

Φ0.8 ~ Φ1.0 |

| Tungsten electrode diameter (mm) |

Φ2.4 、 Φ3.2 |

| Weld welding layer |

multi-layer welding |

| Welding position |

All-position welding |

| Welding torch cooling mode |

Water cooling |

Overview:

The equipment is specially designed for tube and tube sheet welding. It adopts advanced and accurate visual positioning control technology to realize a truly unmanned fully automatic tube sheet welding robot. It is mainly used in chemical industry, various heat exchangers, boilers, power plants, military industry and nuclear power. Fully automatic welding of tube sheets.

Performance characteristics:

◎This system is suitable for flat head welding or fillet welding of heat exchanger tube plate.

◎The main purpose of this system is to solve the unmanned operation of the tube plate, efficient TIG welding, one-person multi-machine control, improve production efficiency, reduce labor intensity.

◎This system consists of TPR2000/TPR3000 body, vision system, 500A program-controlled intelligent welding power supply, special

◎It is composed of welding head, data acquisition system, automatic correction function and automatic arc length adjustment of gun head.

◎The complete system adopts Huaheng's mature automation equipment and technology to ensure efficient, stable and reliable welding quality.